Carton Printing Machine Two Color Printer Slotter Die Cutter In

Line Case Maker

Model:jumbo 2200x5200

When using the TwoColorPrinterSlotterDieCutterInLineCaseMake, it is

important to keep in mind several things to ensure optimal

performance and safety. First and foremost, always follow the

manufacturer's instructions and safety guidelines. Make sure the

machine is properly installed and maintained before use.

To avoid injury, never touch the moving parts of the machine, such

as the printer, slotter, die cutter, or conveyor belt while the

machine is in operation. Always use the proper tools and

accessories when handling the machine, and wear personal protective

equipment, such as safety glasses and gloves.

When working with the printer, make sure to properly load the ink

cartridges and paper. Always avoid using damaged or incompatible

materials, as this can result in poor print quality or damage to

the machine. Additionally, regularly clean the printer heads to

ensure clear and precise prints.

When using the slotter and die cutter, be sure to properly align

and secure the cutting tool before use. Always use the correct size

of cutting tools, as using larger or smaller than required can

result in damage to the machine or material.

Finally, be sure to regularly inspect the machine for any signs of

damage or wear, and address any issues immediately. Following these

guidelines will help ensure safe and efficient operation of the

TwoColorPrinterSlotterDieCutterInLineCaseMake.

| Model | 2200x5200 jumbo |

| Machine Speed(m/min) | 120 |

| Machine Max.speed (pcs/min) | 100 |

| Machine Max.feeder Size(mm) | 2200x5200 |

| Machine min.feeder Size(mm) | 500x1800 |

| Machine Max. printer size (mm) | 2200x5000 |

| thick of printer Plate(mm) | 7.2 |

| Max. slotter Dep (mm) | 750 |

| Max. Thickness of Sheet(mm) | 15 |

Machine size (LxWxH)

| 39000x8300x2800 |

Features

1. The bottom printing printer slotter die cutter in line case

maker consists of lead edge feeder,bottom printers, slotter, die

cutter in line case maker, counter ejector and delivery section.

2. All the units can move, all the rollers gap adjusted by PLC and

touch screen, all the electric parts are Siemens.

3. Gears are made of 20CrMnTi,HRC 55-62, class 6 precision. Main

Bearings SKF, the others are of NSK.

4. Pull roll transfer at all printing units.

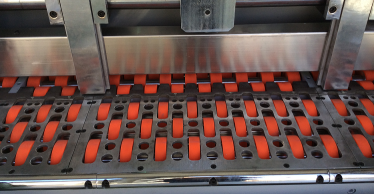

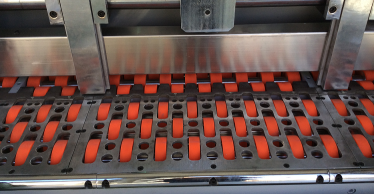

5. Ceramic anilox rollers with LPI arrangements within 220-600LPI

which the Buyer can choose.

6. LED display of speed and finished quantity.

Lead edge feeder

1) Servo control free-pressure feeding system adopted to avoid the

cardboard being pressed ,improve the pressure resistance of

cardboard

2) All the baffles are adjust by electric control

3) Guide rail support the right-left baffle move precise and

smoothly.

4) The feeding rollers are grinded and plated with rigid chrome,

make blance rectification for running stable.

5) Feeding rollers gap adjusted by PLC and touch screen

6) First row of feeding rollers: Upper feeding roller diameter is

132 mm ,seamless steel covered with wear-resistant rubber treated

by balance rectification. Down feeding roller diameter is 156 mm,

seamless steel with knurling surface,treated by balance

rectification.

7) Second row of feeding rollers:Upper feeding roller diameter is

86 mm with dia two 132mm feeding rings ,seamless steel pipe is

plated with chrome and grinded surface,treated by balance

rectification

Down feeding roller diameter is 156 mm, seamless steel pipe is

plated with chrome and grinded surface,treated by balance

rectification.

Bottom Printers

Pull roll transfer

a) The pull roll transfer adopts for the whole process feeding can

feed the cardboard smoothly and precisely;

1. Roller undergoes grinded and plated with rigid chrome, make the

balance rectification for running stable

2. Ceramic anilox roller external diameter is 330¢mm, for solid

printing and high graphic printing(220-600lpi optional);

3. Single blade chamber doctoring blade system with airbag support

to meter the ink volume for even inking result.

4. Printing roller diameter: mm (including 7.2mm printing plate

with liner)

5. Printing pressing roller external diameter is ¢186mm,Steel pipe

is plated with rigid chrome and grinded surface.

6. Ratchet wheels fixed plate axle

7. Loading and unloading printing template, electric controlling

CW/CCW rolling by foot switch

8. Printing roller Horizontal movement is controlled by PLC

adjustment of +/-5mm

Automatic pneumatic lifting gear working with feeding system(Anilox

roller lowers down to touch printing template during feeding and

rises up to leave printing template after stopping feeding.)

9. Printing roller circular move adopts PLC, touch screen control

and inverter adjustment of 360o.(running and stopping can be adjusted)

10. Automatic re-position after washing the printing plate during

the printing process.

11. Automatic ink washing system.

Double Slotter ( two shafts, two blades)

1) Double shaft slotting unit consists of pre creasing wheel, first

slotting, creasing wheel and second slotting

2) Creasing wheel with PU Plated for good creasing and avoiding

paper crack

3) Pre creasing roller and creasing roller gap adjusted by touch

screen control

4) Creasing rollers diameter:110mm,plated with rigid chrome and

grinded surface,treated by balance rectification.

5) Slotting holder rollers diameter:124mm,plated with rigid chrome

and grinded surface,treated by balance rectification.

6) Cast steel slotting guide plates makes slotting precise and

never damage the slotting knife.

7) 9 Crsi Slotting knives

8) All the knives move and slotting holder move adjusted by PLC

control

9) Slotting holder rollers gap adjusted by electric control

Carton Printing Machine is a versatile piece of printing equipment

that is capable of producing high-quality prints on corrugated

cartons. The machine comprises a variety of modules to perform

various operations, including printing, slotting, die-cutting, and

case-making. The in-line case making feature of the machine ensures

that the entire process is streamlined and fast-track.

One significant advantage of the Carton Printing Machine is that it

can print on both sides of the corrugated carton simultaneously.

The Machine uses water-based inks, which dry quickly, ensuring that

the cartons are ready for use immediately after printing. This

feature is particularly useful for those in the packaging industry,

where quick turnaround times are essential.

A two-color printer is an essential component of the Carton

Printing Machine. The printer is capable of creating high-quality

prints with a resolution of up to 600 dpi. The printer's speed is

adjustable, depending on the quality of the print required and the

type of substrate used. The two colors can be used in combination

to create multicolored prints in a single pass. This feature saves

time and reduces production costs.

The Slotter is another important module of the Carton Printing

Machine. It ensures that the corrugated cartons are cut to the

required size and shape. The slotter can perform both straight and

curved cutting operations, depending on the shape of the carton.

The slotting module is designed to ensure that the cuts are precise

and accurate, thereby reducing wastage.