Corrugated Carton Machine Corrugated Board Printing Machine

Model:1600x3600 Jumbo

Use and Characteristics:

QUALITY: Due to high requirements for mechanical quality, raw

materials selection, processing, assembly of industrial control

over the industry standard, using the new design, quality

management system, comprehensive tracking to every detail, delivery

to the customer in both hardware and software are a high quality

equipment.

EFFICIENCY:Patent type feeding width automatic adjustment device

and printing locking device with screw. With 4.0 engineering design

of industrialization, both hardware and software are charged with

the author’s high efficiency tools.

SERVICE:Based on the industry’s first use of PDM design file

management system, complete technical support files, regardless of

the long time can still be credible commitment to customers,

continuous and efficient after-service for the customer support. 24

hours service with 12 engineers .

※MAIN FEATURES

1.printer slotter phase :electric number digital adjust

2. auto ink circulation system

3. combined slotting creasing slitting knives which is easy to

change order.

4.The gear of the machine: Auto lubrication with oil

5.Machine body thickness:50mm

6.automatic seperated, pneumatic lock up.

Standard equipments:

A. Independent Lead Edge Feeder;

B. printers

C. motorized slotter

D. Rotary Die Cutter with auto trimming device;

E. Auto Stacker

1.The Electrical components are used internationally famous

brands.Mainly control is adopted US servo numerical control

positioning technology.Feeding unit,printing unit, slotting

unit,die cutting unit are equipped with colorful PLC touch screen,

with one touch machining setting with zero function can be

connected to ERP system

2. The machine with order memory,easy to change the order

3. With ink shortage alarm to avoid the wastage.

4. In particular with computer remote maintenance;more easier to

resolve equipment failure, more efficiency and reduce the cost

maintenance

| Model | 1600x3600 jumbo | 1800x4200 jumbo | 1800x3600jumbo | 2200*3600 jumbo | 2200*4000 jumbo | 2200*4600 jumbo | 2600*3600 jumbo |

| Machine Speed(m/min) | 150 |

150 | 150 | 120 | 100 | 80 | 80 |

| Machine Max.speed (pcs/min) | 110 |

100 |

100 | 100 | 80 | 60 | 60 |

| Machine Max.feeder Size(mm) | 1500x3600 |

1700x4200 |

188x3600 | 2000x3600 | 2100x4000 | 2100x4600 | 2500x3600 |

| Machine min.feeder Size(mm) | 450x760 | 450x750 | 450x760 | 550x900 | 550x900 | 550x900 | 650x900 |

| Machine Max. printer size (mm) | 1500x3500 | 1600x4000 |

1600x33400 | 2000x3400 | 2000x3800 | 2000x4200 | 2400x3400 |

| thick of printer Plate(mm) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 |

| Max. slotter Dep (mm) | 560 | 750 | 750 | 750 | 750 | 750 | 850 |

| Max. Thickness of Sheet(mm) | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

Machine size (LxWxH)

| 19852x6670x2700 | 15000x5200x2500 | 14000x4500x2300 | 20173x6670x2800 | 20173x7070x2800 | 20173x7670x2800 | 20495x6670x3000 |

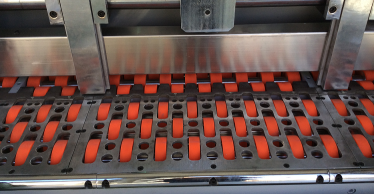

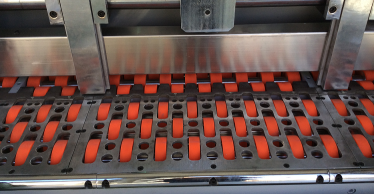

Features of slotting unit

Features for Rotary Die Cutting Unit

| Item | Features |

1. Die cutting mould cylinder( Down cylinder) | 1. Die cutting cylinder is made by high quality steel, fine

grinding, hard chromed. 2. Balance treatment to increase stable running. 3. Die cutting mould fixation screws M10, hole distance at 100mm at

transversal direction and 18 equal units at circumferential

direction. 4. Die cutting wooden mould thickness 13-15mm(five ply),

16-18mm(three ply). |

2. Rubber mat cylinder(Down cylinder) | 1. Mat cylinder uses high quality steel, grinding, hard chromed. 2. Balance treatment for stable running. 3. Rubber mat thickness 8mm, width 250mm. 4. Rubber mat cylinder mechanical rotary direction change 40mm

distance movement structure, movement speed same as the machine

running speed. 5. Manual adjustment of die cutting mould gap, adjustment range:

0-16mm. |

| 3. Phase adjustment device | 1. Satellite gearwheel structure 2. PLC and encoder control of die cutting phase adjustment for

start and stop adjustment. |

| |